A brief explanation of the laser welding process

The laser welding technology used for plastics is based on the light transmission of a polymer and its absorbing characteristics. To be able to weld two plastics together, one material must let laser light pass through and the other material must absorb laser light.

The laser ray energy that is absorbed is converted into heat, resulting in local plasticization and creating a melt on the contact faces between the two materials that cools down to form a strong weld joint.

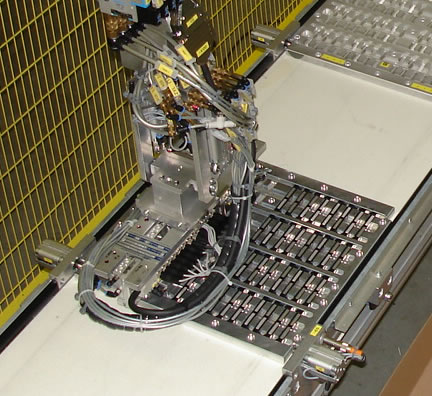

Figure 1

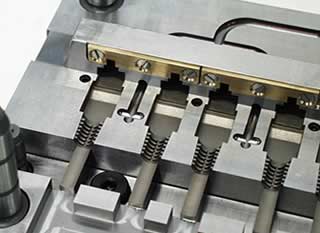

Figure 2

Figure 1 and 2

A: The absorbing material receives the energy and a melt is created.

B: Start of the heat transport to the transparent part.

C: A melt is also created in the transparent part.

D: The entire melt will harden if external pressure is applied.